How Are We Making A Difference In The CleanTech Industry?

Here are a few of the successfully completed projects that we did for our CleanTech clients:

Supply Chain Transparency Platform for the Fashion Industry

Supply chain transparency in the fashion industry addresses the issue of unethical practices, such as labor exploitation and environmental impact, by providing visibility into the production process. This transparency helps brands ensure compliance with ethical standards and sustainability goals. Consumers benefit by making informed purchasing decisions based on the ethical practices of brands.

Additionally, it fosters accountability and trust between brands, suppliers, and customers, ultimately driving positive change in the industry.

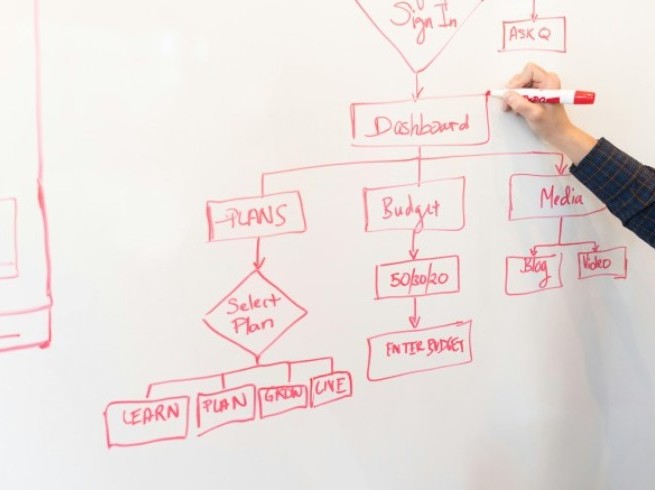

The platform works by providing brands with an easy and intuitive interface to break down the entire production process of an apparel product, right from raw materials to finished products, into different stages. The platform also allows assigning of suppliers and the processes used by them are then assigned to each of the above stages.

By making use of its extensive database of environmental and social impact of each process, the environmental and social impact of each stage of the supply chain is calculated. This information is then shared with consumers and stakeholders, allowing for informed decisions and greater accountability.

Product Life Cycle Assessment (LCA) System for the Apparel Industry

Product life cycle assessment (LCA) is crucial for the apparel industry as it evaluates the environmental footprint of a garment from production to disposal. By understanding the full life cycle, companies can identify areas to reduce resource consumption and emissions, enhancing sustainability. This process also helps brands meet regulatory requirements and cater to the growing consumer demand for eco-friendly products.

The system calculates the footprint of each product at every stage in its life cycle and the results are shown at a highly granular level. Since the early stages of manufacturing like fiber, yarn or dyeing involve combining ingredients or raw materials through a series of chemical or mechanical steps, often involving a continuous or batch production method and in high volume, a custom process manufacturing engine was built.

The engine ensures that for each process, the entirety of a component’s footprint is considered. This includes water usage, fuel consumption, electricity consumption as well as outputs such as wastewater effluents and carbon dioxide equivalent emissions.

The engine also takes care of complexities like multi-stage joins and forks in the production process, formula based production, blending of materials and chemical and physical transformation of materials.

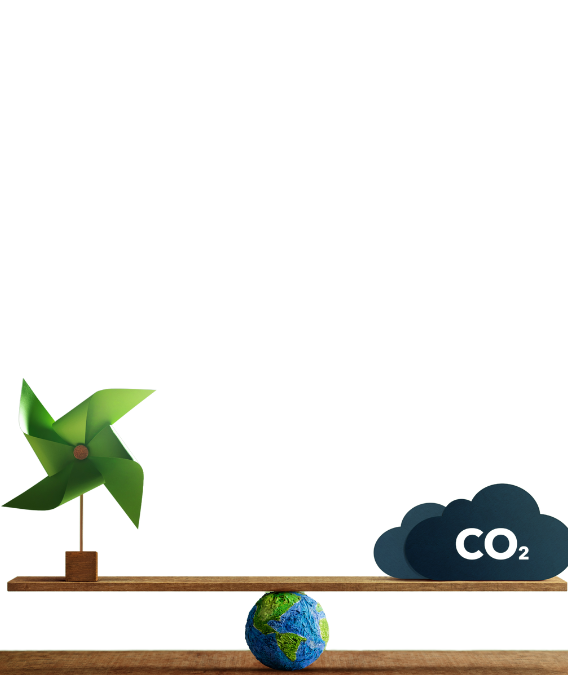

Voluntary Carbon Offset Contribution Platform

Companies that have environmental and social priorities will often want to offset their carbon footprint with carbon offset projects. Communicating this environmental and social contribution and impact to its customers throughout their purchasing journey helps to build trust between them.

The platform aims to facilitate this by acting as a marketplace where Companies and Individuals can offset their footprint by selecting offset projects and purchasing carbon offsets by those projects.

The platform contains a curation of carbon offset projects that have been carefully vetted and verified by a third party. Projects include water donations and plastic offsets as well as tree planting. Platform users have the ability to track the assigned project inventory and progress.

Our Services to Support Your Tech Journey

Our Valued Partners in Progress

Our Projects

Check out our Portfolio Projects

Sustainability